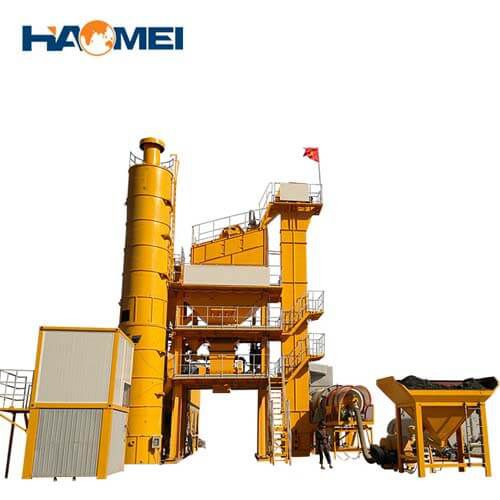

DHB40 Drum Asphalt Mixing plant manufacturers provide low price high quality Asphalt Mixing plant made in China for sale.

Productivity (standard conditions): 40 t/h

Oil Consumption (standard conditions): 5.5-7kg/t

Operation mode: manual control

The Figure Dimension: (length×width×height): 30×16×6m

DHB40 Drum Asphalt Mixing plant made in China not only screw conveyor, pneumatic components and other excellent accessories, there is a particularly excellent stirring host. These ensure the asphalt mixing station in the work of high accuracy, high reliability and long service life. At the same time, each maintenance part of the asphalt mixing station is equipped with a walking platform or inspection ladder, and has sufficient operating space. The mixing host can be equipped with a high-pressure automatic cleaning system, with automatic alarm functions for oil shortage and over-temperature, which is convenient for equipment maintenance.

High quality low price DHB40 Drum Asphalt Mixing plant has good environmental protection function. During the operation of the machine, the powder control is performed in a fully closed system. The powder tank adopts high-efficiency dust collector / fog spraying and other methods to greatly reduce the pollution of dust to the environment. At the same time, the asphalt mixing The station adopts noise reduction device for the exhaust system and discharge equipment of the pneumatic system to effectively reduce noise pollution.

Nowadays, in the field of road and bridge construction engineering, people are very familiar with the DHB40 Drum Asphalt Mixing plant for sale, because this is an important link in providing construction materials, but in the engineering construction, in order to better supply raw materials, the asphalt mixing station is constructed And installation, then we must first make a basic selection and measurement of the site, and make a unified plan for the use and installation of facilities and equipment, because this can meet the future use requirements, because the role of asphalt mixing stations is very important in many projects of.

In general, for the construction of asphalt mixing stations, a more open site will be selected, because during the production and processing process, many large engineering vehicles will transport the asphalt concrete, so the area requirements for the site are relatively Strict, otherwise it will seriously affect the output of processing raw materials. In the process of infrastructure construction, the specific measurement and planning of the selected equipment size must be carried out first, otherwise it will seriously affect the installation and use of equipment.

Through this understanding, people have a preliminary plan for the construction of high quality DHB40 Drum Asphalt Mixing plant. In the planning process, it is necessary to consider the purchase of equipment. Because many mechanical equipment need to be installed in the prefabricated plate during the use, so for The size requirements are relatively strict. If the construction is not carried out in accordance with the size requirements of the mechanical equipment, it will affect the installation and use of the entire set of equipment.

1. DHB40 Drum Asphalt Mixing plant made in China during operation, in addition to ensuring that the asphalt mixing station equipment is in good condition, it should also be equipped with a mineral water content detector and a finished product analyzer, and often check the relevant data for operators to adjust operations in a timely manner, etc. To keep the device in good condition.

2. In addition to affecting the production capacity, the water content of the minerals also determines the main factor of fuel consumption. Sheds should be added.

3. DHB40 Drum Asphalt Mixing plant manufacturer says, before operation, fully check whether all working parts and devices of the DHB40 Drum Asphalt Mixing plant for sale are intact and normal. If there is a problem, it must be properly handled before operation, and must not be carried out with illness.

4. The operation must be carried out in strict accordance with the procedures and precautions specified in the instruction manual. After the ignition is normal, the dust collector should be monitored for normal operation to ensure that the drying drum burns under negative pressure. After the production starts, the hot material elevator and agitator should be monitored for normal operation to coordinate the operation of other parts.

5. After the operation for low price DHB40 Drum Asphalt Mixing plant is finished, the feeding should be stopped, the burner should be gradually turned off, the stirrer should be washed with hot fines, and the hot material in the drying drum and the agitator should be drained. When the temperature of the drying drum drops 45 to 500C, stop the drying drum , Blower, dust removal system operation, cut off the main power supply of the operating room.

6. Use a wet dust collector. The flue gas contains sulfur and other elements. Purified water will be acidified and have a corrosive effect on metals. Therefore, a neutralizer must be added to the water and the circulating water must be replaced regularly.

| Specification | Unit | Value |

|---|---|---|

Productivity (under standard conditions) | t/h | 40 |

Oil consumption (under standard conditions) | kg/t | 5.5-7 |

Operation mode | manual control | |

Aggregate Bin | Quantity | 3 |

Figure dimension | m | (length×width ×height): 30×16×6 |

Total installed power | kw | 57.15 |

After a Polish company wins a road construction project, the relevant person in charge considers that it is a large and medium-sized engineering project,

Read More